Thermal Transfer vs. Direct Thermal: A Few Pointers

When should you use thermal transfer or direct thermal? What's the difference?

Direct thermal label printing is more of a niche technology then a mainstream one. This is why it is chiefly used in several small scale markets such as poultry meat and dairy products for labeling purposes. But now, improvements in cutting edge technology have also effectively served to increase both the nature as well as the scope of direct thermal paper technology.

o The Key Differences Between Direct Thermal Printing as Well as Thermal Transfer Printing

These two types of printing have a few differences that are explained below:

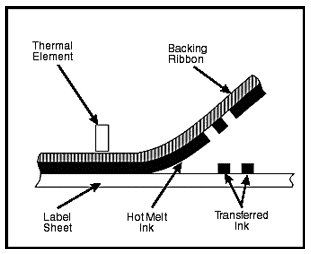

o Thermal Transfer Printing

Stripped off anything but the bare essentials, thermal transfer printing is a process that utilizes a specific type of thermal ribbon while direct thermal printing has no ribbon installed as such.

As a matter of fact, the process of thermal transfer printing essentially involves the thermal printers’ head elements or dots being responsible for heating the back portion of a thermal transfer ribbon. The latter will be utilized for the purpose of both melting and then subsequently transferring the ‘transference’ compounds on to the front end side of the ribbon onto the labeling material itself. This effectively creates the freshly printed image.

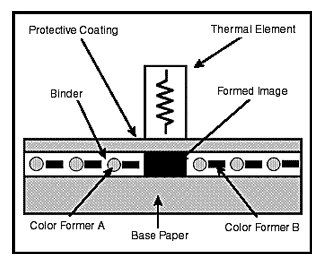

o Direct Thermal Printing

On the other hand, this process requires a highly heat-sensitive label material. Here, the print head elements will be in direct contact with the heat sensitive materials, that tougher constitute the transference compounds. As a matter of fact, the heat from the elements will effectively cause an immediate color change in the transference material and they will, in turn, create the printed image.

o Label transfers and The Environment

In today’s world, the idea of creating as small an ecological foot print as possible, has gained widespread popularity. It is now deemed very important to look for solutions that reduce waste, lower carbon emissions and ensure sustainability.

Here, direct thermal printing technology has a clear advantage since it effectively eliminates the use of thermal ribbons that are pivotal to the thermal transfer process and that are also made with the help of crude oil products. This is why the willful elimination of the widespread use of thermal transfer ribbon is quite likely to have a really positive impact on any company’s goal for a reduced carbon footprint.

However, every organization has its own applications and usage-related requirements. Therefore, they will have to evaluate both of these technologies so as to come up with a solution that serves them the best.

For more information on thermal transfer and direct thermal printing or for all your labeling and printing needs, call us as (800) 643-2664

and immediately talk to one of our friendly representatives; or chat us up on Facebook

, Twitter

, Google+

and LinkedIn

!

Keep your thermal printers running! Download our FREE maintenance ebook . click here

Contract Customer Request Forms