Overcoming Challenges In Food Labeling For Better Traceability

Progress has been made but there is still much work to be done.

There is a strong need to trace any kind of food contamination back to its source. The Produce Traceability Initiative was launched with this key goal in mind. However, food labeling is yet to become a universal practice.

It will still take a few years for the industry to come close to this vital goal of food labeling.

The good news is that major food producers are attaching labels on their packages. However, many small farmers are still not complying.

One reason for this is that people often don’t do something that incurs expenses unless it is legally mandatory. However, even though not everyone is labeling their packages, the situation is gradually improving with the passage of time.

Increased labeling

More and more food producers are beginning to see the benefits of labeling packages to trace the origins of its content. Hence, the industry is slowly but surely moving towards universal compliance.

Major retailers are now requesting food producers to provide information about their produce and to label their packages. Whole Foods Market and Wal-Mart are some of the major retailers that have made it mandatory for food producers to provide this information.

Big retailers require food labeling since they will not have to begin their own investigation in the event of food contamination if labels containing necessary information are attached to contaminated boxes.

Standardization

The industry needs a standard method to access, store and transmit information to make progress in this regard. This is necessary for dealing with food recalls. With standard methods in place for dealing with data, retailers will have the information that they need at their fingertips. It will be easy for retailers to provide this key information to the USDA when it initiates an investigation for tracing the sources of food contamination.

Retailers are less likely to come under the scrutiny of the USDA if they are able to supply necessary information at short notice. Therefore, major retailers like Wal-Mart and Wholesale Grocers are implementing systems to transmit information electronically.

The Cloud

A cloud-based system that is accessible to all stakeholders will be most helpful in this regard. Not everyone may be able to write data to the cloud, however, everyone will be able to retrieve necessary information.

Putting codes on packages is the first step towards unravelling the source of the contamination. However, it may still be necessary to call up the shipper to retrieve further information.

Having a universally accessible cloud system will have its own unique benefits. Customers will for the first time be able to access information about food contamination that was previously unavailable. This will prove to be a big boon to producers since transparency will help to foster trust and project a sense of responsibility on part of food businesses.

The G-10 number may become available to consumers. This number is used worldwide to provide information about the source. With this number, consumers will be able to find out from the website the source of their food.

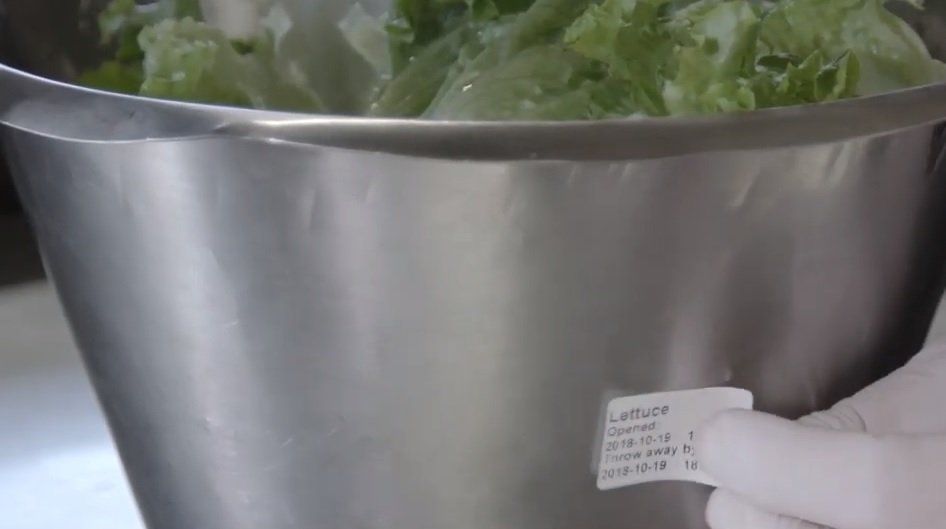

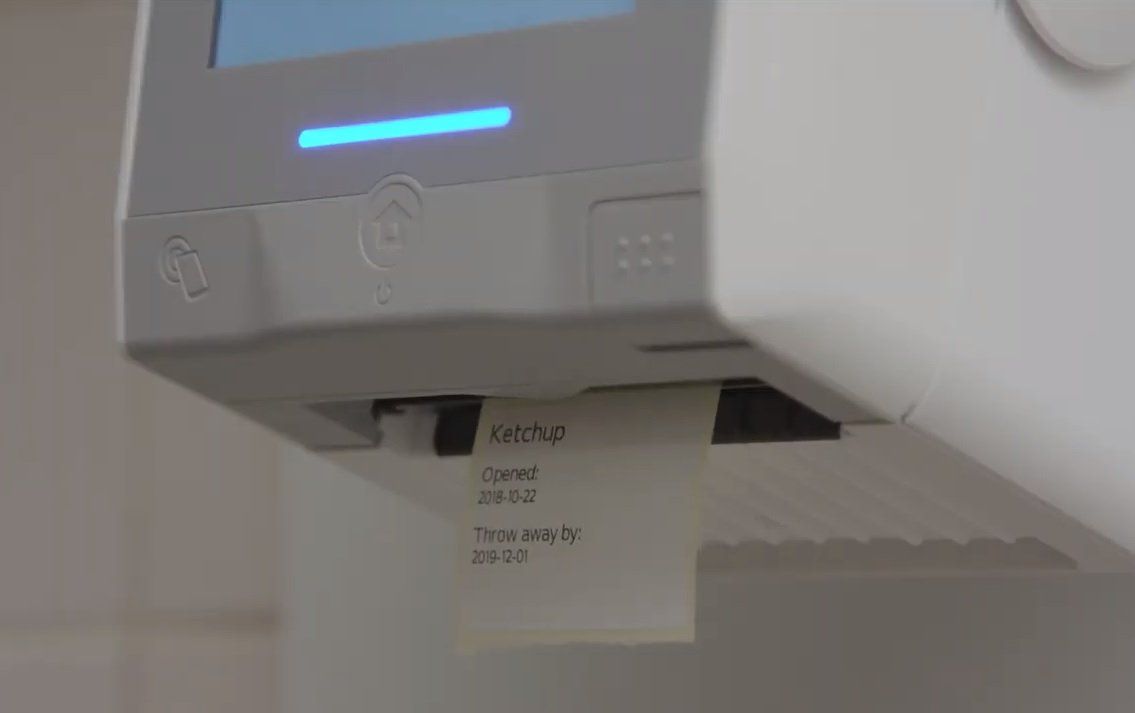

The SATO FX3-LX was built for easily creating labels for food & produce safety. View the SATO FX3-LX Now >>

To learn more about how the SATO FX3-LX

can help with food traceability, call and talk to one of our Printer & Barcode Technology Specialists at (800) 643-2664

. We are here to help!

Get More Information On The SATO FX3-LX