Thermal Printhead Failure – Are You Ready?

Do you know what to do if your printhead on your thermal label printer suddenly failed?

Even something as small as a thermal label printer failing at an essential time can put your business into a state of distress. So, when something as important as a thermal printhead failure occurs, you need to be prepared.

Unfortunately, thermal printheads will eventually fail. There are ways to prevent it from happening at a critical time however, by extending the life of the thermal printhead. Just like with anything that fails, there are causes for its failure. For instance, brake pads on a car after a while due to friction are worn down causing them to fail and need to be replaced.

For thermal printheads, there are 4 major causes of failure:

-

Abrasion – wearing down caused by the rubbing and friction of the thermal printhead

-

Electrostatic Discharge – the static build-up that is created released without careful counter measures

-

Heat settings – printer settings controlling the heat of the thermal printhead

-

Residue build-up – dust and other particles that accumulate up on the thermal printhead, and if not cleaned, can cause damage to the thermal printhead

With abrasion there is not much you can do to prevent it. Due to the design of the thermal label printer, the friction and the wear and tear will always be present, unless of course you find way to rewrite the laws of friction. However, there are a couple quick tips. The key to the reduction of wear and tear is to make the least amount of contact with the other machine parts as possible. So, if possible, use media that covers the whole contact surface of the thermal printhead. Also, look at the type of printing you are doing (direct thermal, thermal transfer, etc.). Different types of printing are easier on the printer, then others.

Electrostatic build-up is a tough one. Everybody knows that static electricity plus electronics is a wonder way to make very expensive paper weights, so how is this helped. Since we can’t really prevent the build-up, we can only control how it’s discharged. Therefore, when you do have to come in contact with the thermal printhead, make sure you have gloves on and that you are well-grounded to prevent damage to the thermal printhead. The one good thing about this cause is that it really only comes into play when you have to touch the thermal printhead, and does not have consistent over time damage like the other factors do.

Heat settings is one of the simplest of causes to deal with, but is also one of the most unavoidable. Heat settings effects on the thermal label printer are simply the higher the heat, the more damage to the printer. However, the same goes for the quality of the printing, with the higher the heat settings, the higher the quality of printing. So the key is to find the right balance, where the heat is as low as it can be set, while maintaining the quality that you need the printer to perform at.

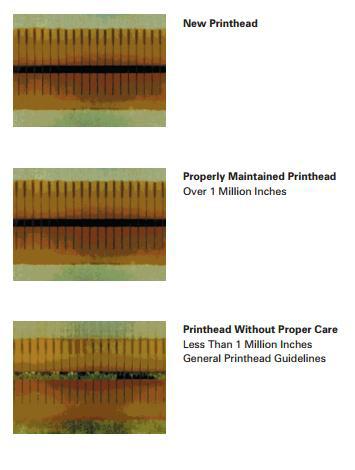

Last but not least, residue build-up this is probably one of the biggest causes for the failure of thermal printheads, because people forget to clean their thermal printheads. Residue build-up can happen in a variety of ways from adhesive oozing from label printing, incorrectly installed thermal printheads (upside-down), to just plain use of the printer. Fortunately it is easy to fix. All you have to do is clean your printer regularly, after about every roll of media should be fine. If not cleaned, it could damage the thermal printhead, or at the very least increase the abrasion of the thermal printhead.

With these tips you can hopefully avoid those unfortunately timed failures. But there are no guarantees. The fact that nobody knows when a thermal printhead will eventually fail prevents that. However, if we make it fail less often, the odds are it won’t fail at a critical time.

There is one guaranteed way to prevent being out a thermal label printer at a critical time. That is to

have a spare printhead. Just like in movies when the original plan goes wrong, they think of a Plan B (if they don’t have one already). This way if the thermal printhead does fail at a critical time, there is a

spare printhead

to pop in until a new one can be acquired. So, use these tips to extend the life of your thermal printhead, and when it does inevitably fail, be prepared to handle it. As always, you can call MIDCOM at (800) 643-2664 or chat us up on

Facebook

, Twitter

,

Google+

and

LinkedIn

!