Manufacturing Competition Requires Better Traceability

Manufacturing competition requires faster processes – quality & traceability

May seem like I’m a bit of a broken record at times; going on and on about it. But it can’t be said enough. To remain competitive it is imperative that the speed of your barcode traceability improves. The use of proper automated barcoding scanning equipment and printers do play an important role in achieving faster results in tracking and overall responsiveness. Yes, I do seem like a broken record.

So, what I’m saying is that it is essential that companies really look at the cost benefits of investing and improving their data capture systems with updated more automated thermal printers and barcode scanners. Have you?

Below are links to a few case studies and white papers I found that demonstrate and provide solid evidence on how many businesses across various industries are doing just that and how their business responsiveness and efficiencies have dramatically improved and their inventory and distribution costs have seen cost savings by doing so.

Many companies are forced either through new governmental laws and trade regulations (such as the US Bioterrorism Act or European Union Food Law in the case of the foodservice supply chain industry).1 In this case, the foodservice supply chain industry utilized RSS bar code and RFID technologies to improve safety, lower operating expenses and improve efficiencies, and meet compliance requirements.

For those that haven’t been forced to implement by regulation, improving speed of traceability benefits in many ways. Not only are your operations more efficient overall, but are better able to deal with issues when they arise. Faster identification of picking and shipping errors, leads to faster resolution thus eliminating costly measures to identify and correct the mistake throughout the system and customer satisfaction issues. Same with dealing with product recalls. Companies are the much better prepared to identify, locate and communicate issue and execute resolution faster, thus saving crucial time and cost savings, in the short-term and long-term.

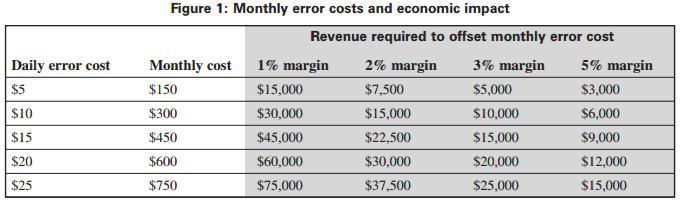

Below is a great graphic example or snapshot of the costs that a simple picking error can generate.

Source: Bar Coding and RFID: The Key to Traceability and Safety in the Food Services Supply Chain, Zebra Technologies.2

So, if you are looking to:

- Have Immediate and accurate capture of production inventory

- Increase delivery performance and customer satisfaction

- Reduce financial and brand risks, and enhance vendor/supplier accountability

- Effectively manage product history – through all stages of manufacturing to customer

- Accurate accounting of manufactured goods process

- Increase manufacturing control for materials management

- Inventory management optimization and quality assurance

- Eliminate costly and inaccurate manual warehouse processes and handling

then the time is now to address your operations and review your barcoding needs.

For more information on RFID systems, manufacturing traceability solutions and barcode scanning and printer options, call us as (800) 643-2664 and immediately talk to one of our friendly representatives; or chat us up on Facebook , Twitter , Google+ and LinkedIn !

Sources:

1 https://www.zebra.com/us/en/solutions/manufacturing-solutions/quality-traceability.html

2 http://www.barcodegear.com/sites/default/files/solution-white-papers/Traceability%20and%20Safety%20i...

https://www.intermec.com/public-files/brochures/en/food-traceability-brochure.pdf